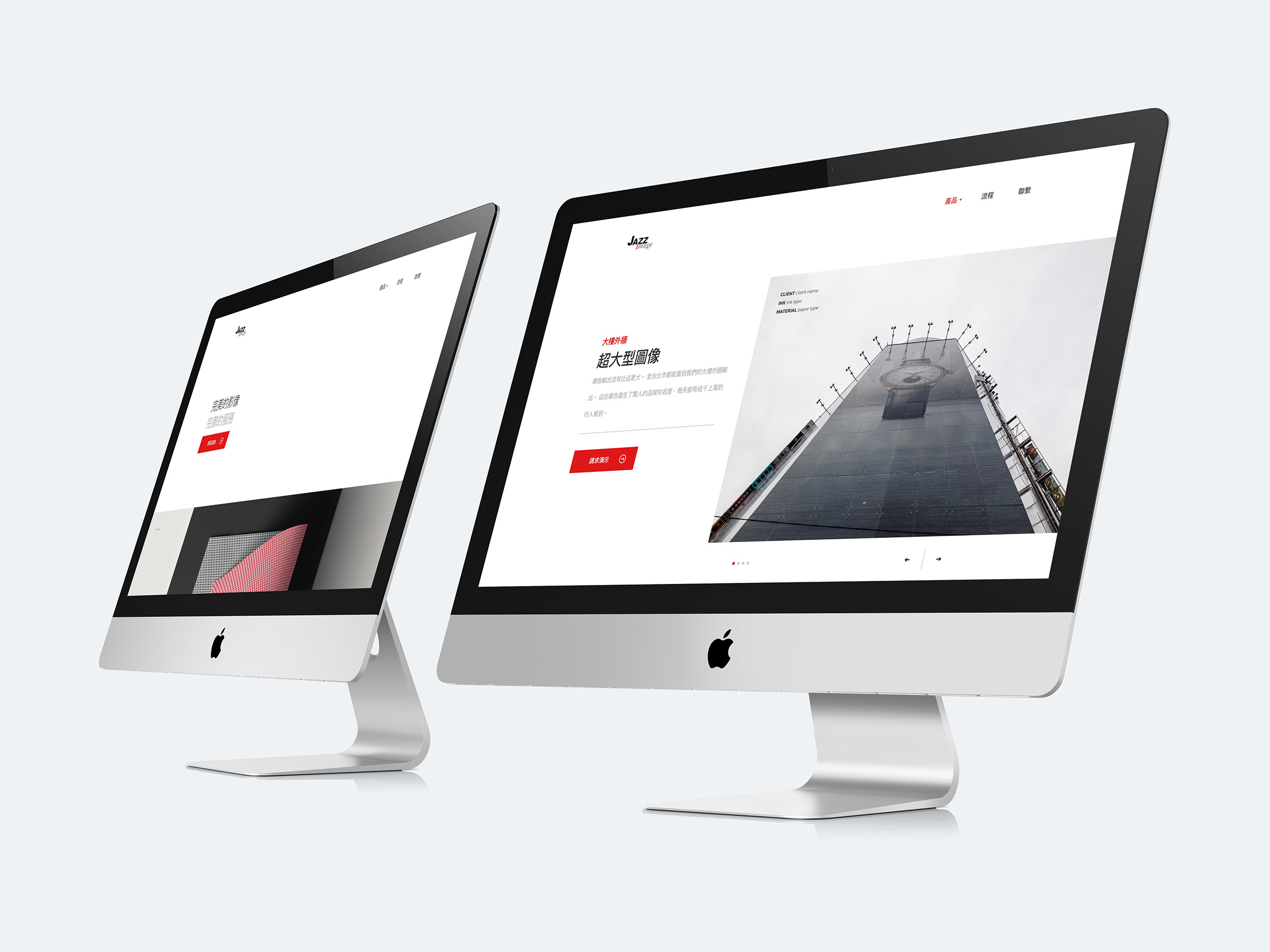

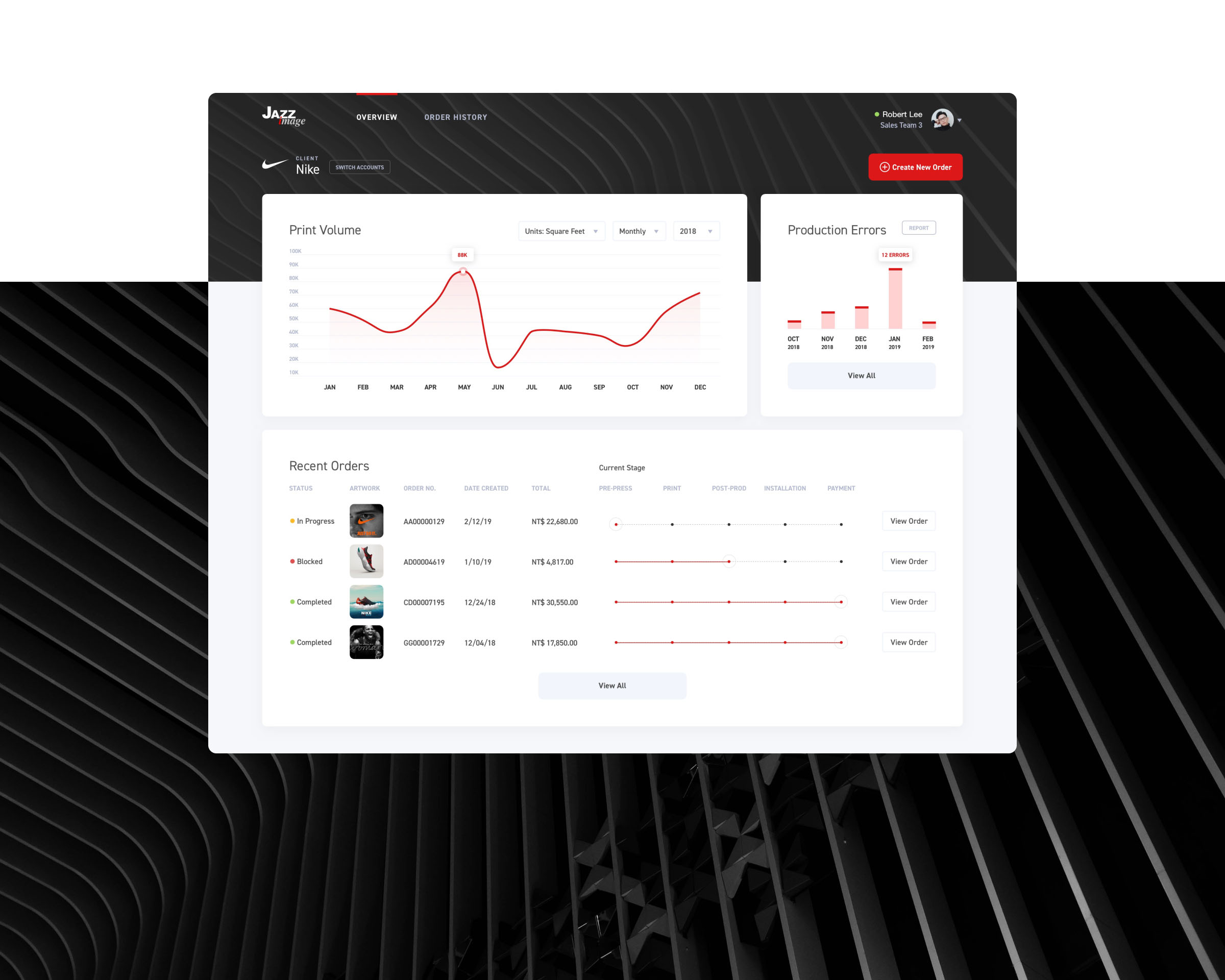

Jazz Image

Modernizing Traditional Large-Scale Printing

For the past 40 years, Jazz Image has been Taiwan’s market leader in out-of-home (OOH) commercial print for advertising, signage, architecture, and creative campaigns. Their clientele consists of the world’s largest brands, such as Adidas, Louis Vuitton, Lexus, Gap, and Disney.

Role

Head of Design

Responsibilities

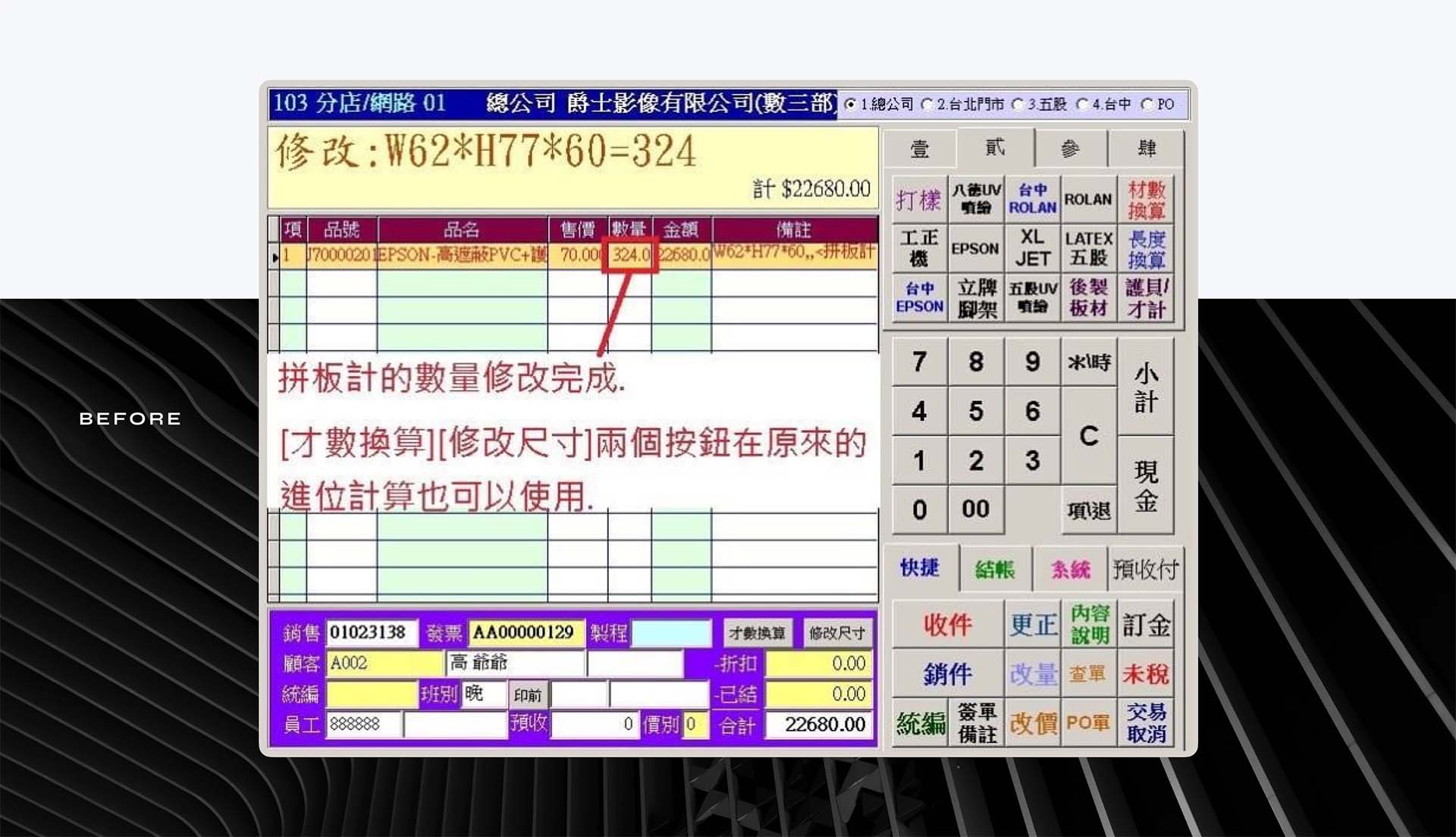

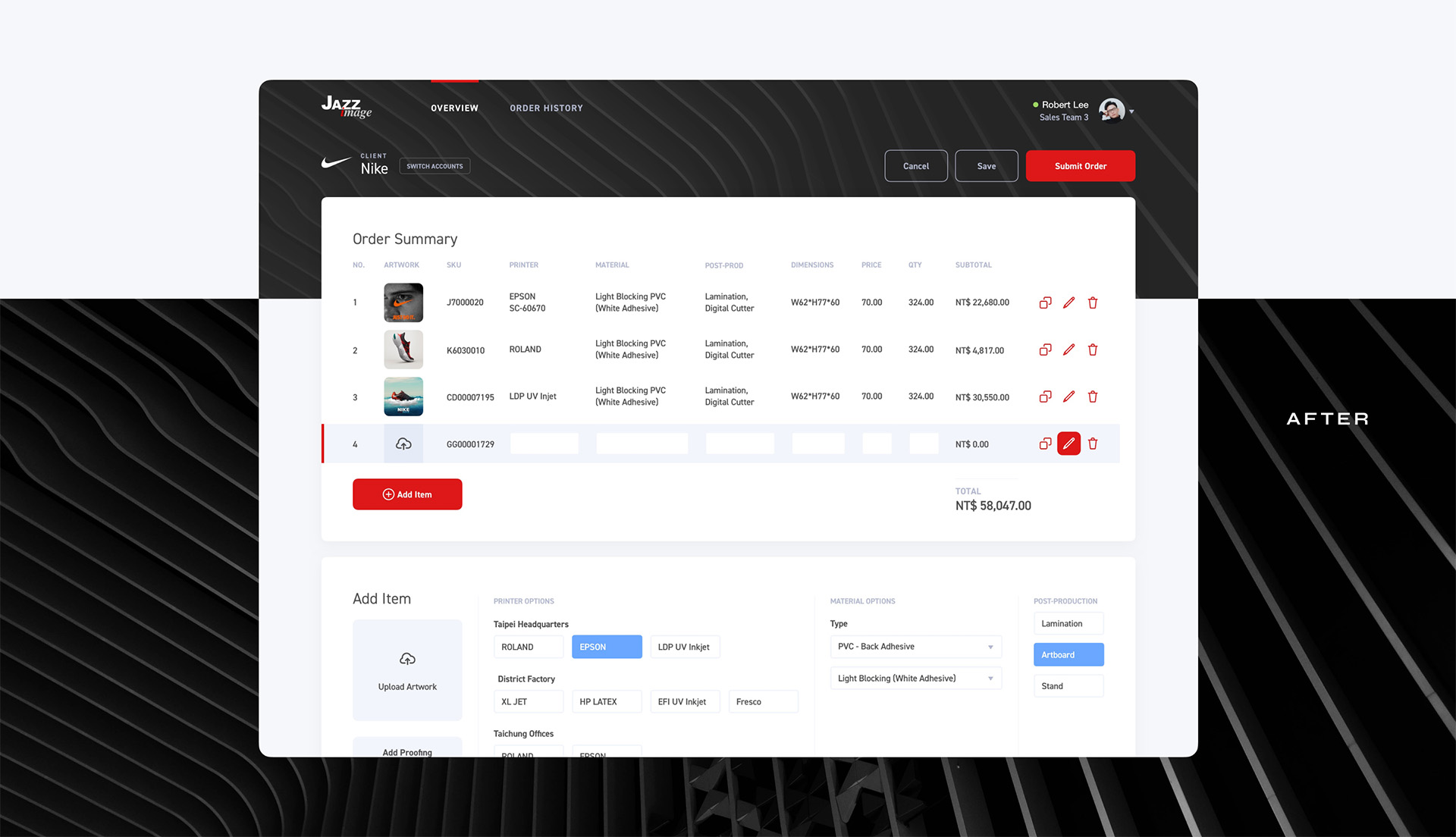

Revamp the company’s ERP (enterprise resource planning) system, an internal tool used to manage orders within the print production process, as well as update the company's branding and marketing assets

Challenges in Printing

1. Unpredictable Demand

Clients expect rapid turnaround and don’t often give notice in advance when placing orders.

2. Low Error Tolerance

The large-format print business has a very low tolerance for errors. The smallest mistakes in color matching, cutting, or choosing the wrong adhesive can result in an entire project having to get reprinted. Sometimes that could mean an entire high-rise, bullet train, or airplane.

3. Unknown Order Status

Account management teams frequently did not know the status of their orders. Prints that were completed and ready to be shipped stood idle. Prints might be paused because they required clarification from the customer. The gap in communication between the production teams and the account management teams resulted in delays and errors.

Anticipate Demand

By tracking when major brands submit print orders year over year, we can predict when future orders are likely to come. This allows the production team to better manage inventory and prevent traffic jams when multiple large orders come in simultaneously.

Quickly Identify Problems

Frequently, print defects weren't caught until the print was on site ready for installation. This causes delays for the project, wasted time for team members and contractors, and the need to reapply for permits. Identifying problems the moment they occur is the best way to minimize unnecessary costs.

Learn From Mistakes

Making it easy for team members to report errors throughout the production process ensures that all problems are consistently and accurately captured. Only then can managers study where these mistakes are occuring and implement systematic solutions in the production line. This idea draws from the jidoka concept in the Toyota Production System (TPS).

Selected Works

Sans(Coming Soon)

WingmateFriends Don't Let Friends Date Alone

Ubiquity6Capture & Edit in Augmented Reality

MindbloomPsychedelic Therapy is Here

Zero by RoA New Way to Quit Smoking

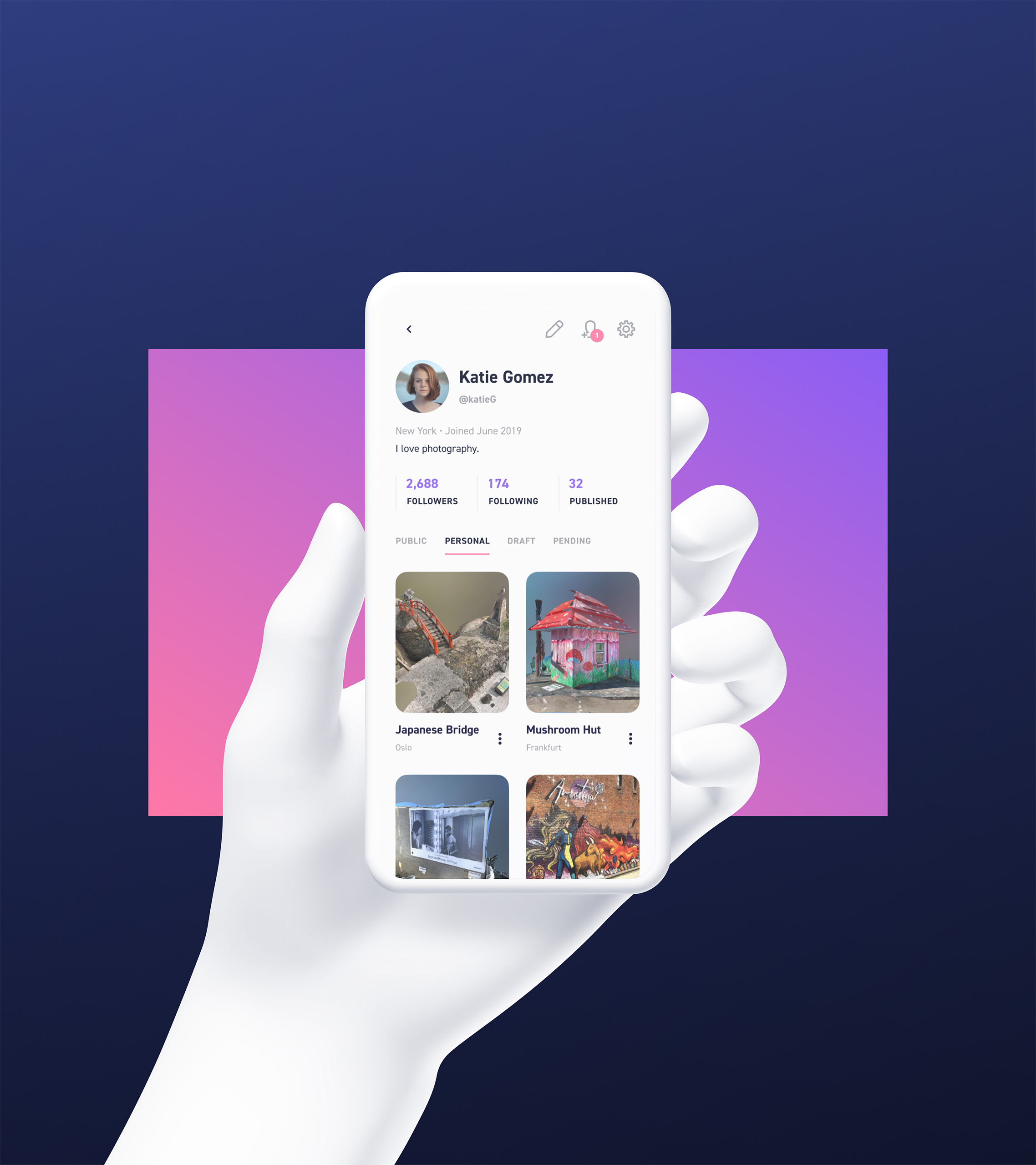

Project CollectionFreelance & Independent Works

Eight SleepSleep Stories